We like to be in close, personal contact with our customers so that we can get a clear picture of where our products are being used. This puts us in a position to offer a wide range of products, both in standard and in special designs. Our products are always manufactured to conform to your requirements.

Agosi sheets, tubes and wires are manufactured with the same degree of diligence as a CNC precision turned part from our production facility. As our customers use our semi-finished products for a variety of applications, the alloys must remain consistent in quality and it is our constant quality control and material analysis that guarantee the reliability of the functional properties.

Your contact:

Roland Hiller,

Divisional Sales Manager Lifestyle Products

phone: +49 (0) 7231 960-242

fax: +49 (0) 7231 650-212

roland.hiller@agosi.de

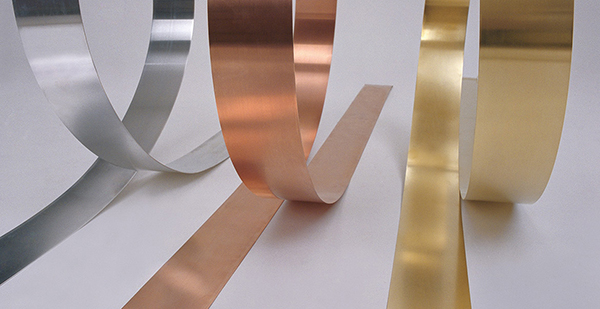

The basis for brilliant results

Sheets and strips with excellent deep drawing characteristics for simple and efficient processing into high-quality end products, available with a brush finish or, by special request, with bright-rolled surfaces. Required hardness and dimension tolerances are monitored by our laboratories. Be it sheets, strips or plates – only the best quality ensures efficient processing further down the line.

Keep a high profile – with high-class end products

Whether annealed or hardened, round or D-section, or in a variety of other cross-sections – our wires, rods and profiles are an important prerequisite for high-quality end products.

Precision pays

Our product range would not be complete without high-quality tubes. The precision and care exercised during their manufacture ensure that they are the right choice wherever accuracy and reliability are required. Whether drawn or hammered, seamless tubes with precision measurements and exemplary characteristics are ideal for each application, for industrial production as well as in the goldsmith‘s workshop.

Your benefit

Where quality counts

Our highly qualified employees use the latest lathes and milling machines to develop and produce precision parts based on customer drawings, fulfilling the very highest quality demands. Customers benefit from a high level of accuracy, close tolerances, improved surface quality and savings in material.

Agosi’s production facilities are designed for small-batch and large-scale production and process all common alloys.

Areas of application: jewellery and watch industry, writing utensil industry.

Our range of machinery includes

CNC lathe from 1-220 mm

fixed headstock automatic lathes

sliding headstock automatic lathe

3- and 5-axis milling machines